The gale of digital transformation is sweeping every industry as the world recoups from a devastating pandemic. Businesses are making the rapid switch to digital. Miners, too, are adapting faster than anticipated to these changes. One of the crucial drivers of this change is analytics. You may wonder what analytics has to do with mining. A sector that has used legacy technology and thrived on boots-on-the-ground experience. Imagine the amount of data that mining activity generates at each stage of the value chain-extraction, sampling, processing and transportation. To capture this stream of data, sensors are embedded across all stages of mining. Analytics can cull out, collate and process this data to extract actionable insights that power evidence-based decisions, boost productivity and help achieve robust business outcomes.

Why Mining Needs The Touch Of Analytics

According to the World Economic Forum (WEF), the mining and metal industry is expected to grow by USD 10.6 billion between 2016 and 2025. Although analytics in mining is still in its infancy, it has started to add value to operations. Mining operates in challenging conditions - declining productivity, volatile commodity prices, and maturation of existing mines resulting in lower ore grades and longer haul distances. A deluge of data is collected each day at mines, but miners cannot consolidate this data and make the most of it. It’s a two-pronged challenge:

- Selecting the appropriate data for informed decision making

- Consolidating data from multiple vendors, platforms, and systems

Counting The Benefits….

By tapping advanced analytics, enterprises can leverage the value, volume, velocity, and variability of data across extraction, intermediate transportation, and final transportation to plants. Mining companies can monitor operations, track sensors, and analyze human behavior using real-time data and advanced analytics. Many variables are involved in these, including temperature, location, heart rate, CO, gas, wind speed, dust, etc. Also, analytics can be used to predict tunnel collapses, like near misses. Plus, there are other benefits to mine like:-:-

- Smart Partnership: A single data source streamlines collaboration across the organization, ensuring new partnership models with operators, OEMs, and service providers.

- Business Intelligence: It helps to detect areas that are real cost drivers, aiding quicker decision making and enhancing performance.

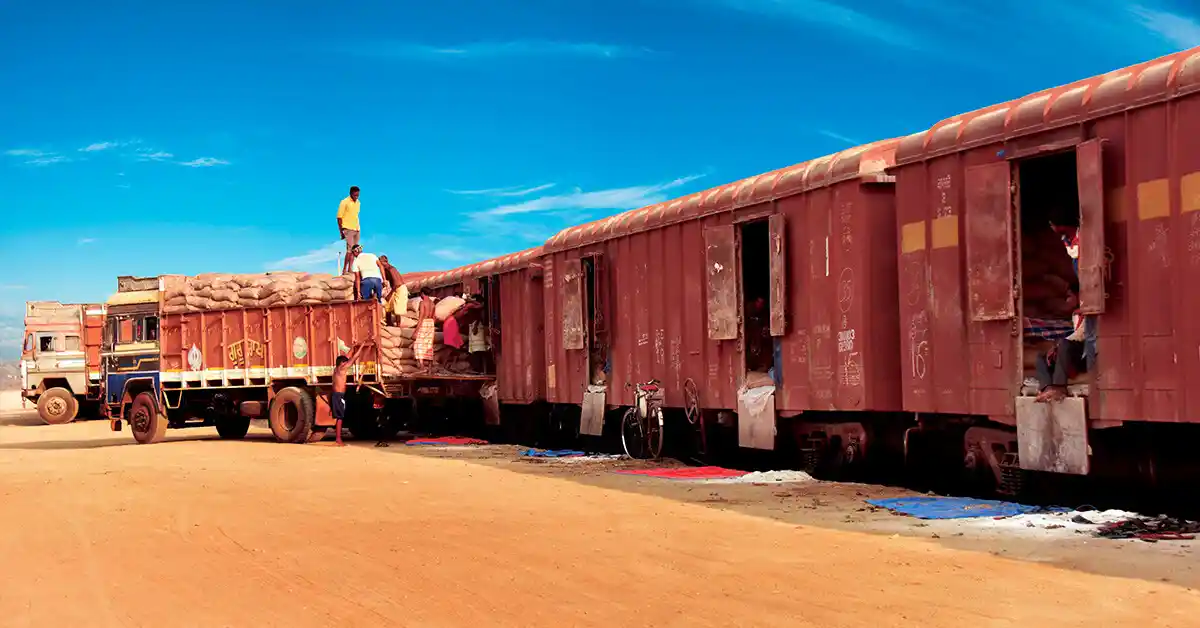

- Enhancing logistics performance: Transportation forms the nucleus of the mining industry. Advanced analytics can spot the areas that need a boost in efficiency

.jpg)

How CSM Technologies has embedded Analytics in mine value chain

We have developed a suite of digital-first mining solutions that help enterprises make the most of data analytics for transforming business outcomes. Be it our end-to-end ore accounting & management system or the mine logistics automation solution; a striking takeaway is the intelligent use of analytics. To illustrate, the use of Internet of Things (IoT) at numerous touchpoints ensures seamless data capture and analytics to stem duplication and ore theft. Analytics is also used to monitor the production and transportation of minerals and the number of trucks and trips they take. By enabling complete visibility, analytics reduce operational costs. Additionally, our analytics platform uses analytical modelling to interpret structured data to determine the model needed to address the challenge, from machine learning to deep learning, depending on the complexity of the business case. Analytics is the key to delivering Mining 4.0 for miners who want to improve productivity and performance without compromising safety or sustainability.

We will verify and publish your comment soon.