Only a few days back, Google created a disruption, promising delight. It announced Supply Chain Twin, a new Google Cloud solution that lets companies build a digital twin by organizing data to have a complete, real-time view of the entire supply chain. Using Supply Chain Twin, customers can gain a deeper understanding of their operations, allowing them to optimize functions in the supply chain from sourcing to planning and distribution to logistics. The 'digital twin' approach to simulation is gaining currency in many domains. Even mining, which has been historically viewed as an analogue business, is fast catching up with automation in logistics. Automation promises solid operational outcomes and prepares the sector for Mining 4.0, where every component or process- trucks, drills, trains, back-office, procurement and the supply chain is seeing a digital transformation.

The Need to Switch to Digital Logistics

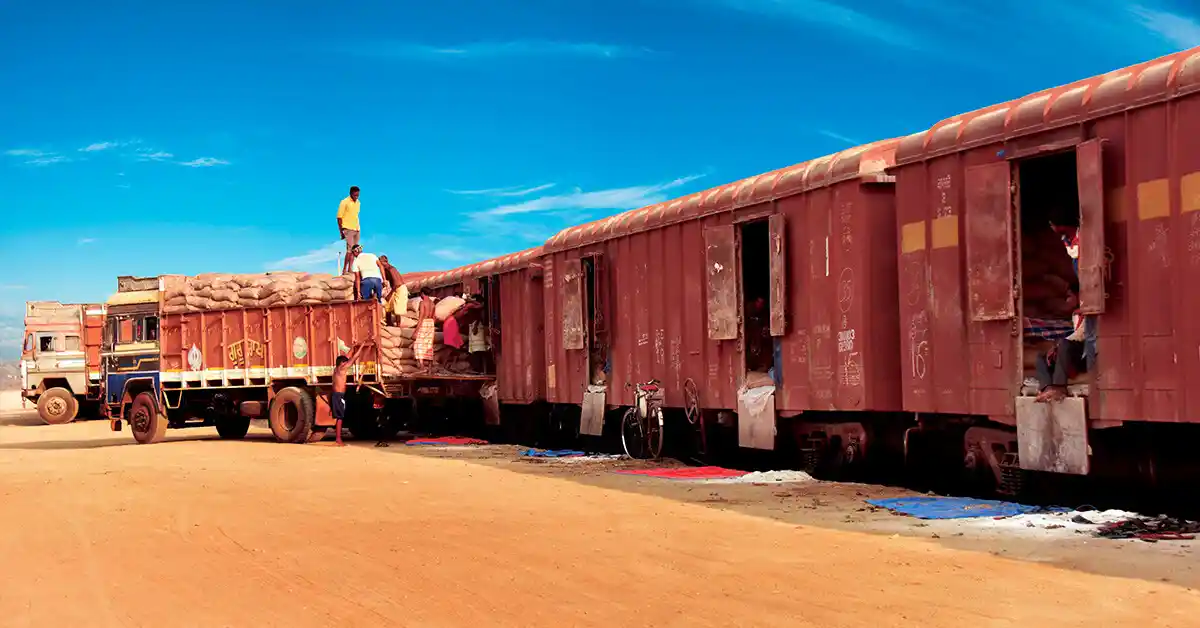

Logistics forms the fulcrum of the mining business lever. It's challenging to have seamless logistics if you consider the ambience and the conditions in which mining activity happens. Transportation is complex in any industry, but the mining sector is uniquely placed. Mines operate in the remote hinterland, furlongs away from a bustling city. Some of the mines may even be located far from ports- this poses an immense challenge to move out the mined matter to the final consumption point. That apart, mines need heavy equipment like excavators, back loaders, dumpers for operations. The transportation of such equipment is an additional challenge to navigate. Usually, logistics in mining is multi-modal- it uses ports, railway rakes, trucks and trawlers. Hence, mining companies need to optimize logistics with digital interventions. Algorithms powered by Artificial Intelligence (AI) and Machine Learning (ML) can help miners track every stage of the supply chain, minimize in-transit theft and ensure their product reaches the final touchpoint on time.

Benefits from Digital Makeover of Logistics

By embracing automation in logistics, mining behemoth Rio Tinto has shown the way. It's iron ore business operates the world's first fully autonomous, heavy-haul long-distance railway system – AutoHaul, which has completed more than seven million kilometres. Rio also runs a fleet of 130+ autonomous trucks across its iron ore mines as part of its autonomous haulage operations. Digitalizing multi-modal logistics offers numerous benefits:

- Better visibility

- Enables on-time deliveries through tracking of vehicles

- Real-time monitoring of minerals movement within mine premises and outside with centralized management

- Reduced security incidents with instantaneous alarms in case of route violations/ unnecessary stoppages

- Generated maps for dynamic geofencing with GPS-enabled video streams to track distance travelled by trucks

- Improved operational efficiency

- Improved production planning and supply chain activities related to vehicles and mining operations with online reporting on availability and breakdown

- Facilitates proactive decision making with dynamic route optimization

- Simplified monitoring and co-ordination, leading to flexible mining operations

CSM's Mine Logistics Automation System

CSM Technologies has developed an end-to-end mining logistics automation system to help miners tackle the multi-modal transportation challenge. The solution can meet some of the most challenging logistics problems like pilferage, untraceable material movement and porous/opaque movement of mineral carrying vehicles plying within the mining premises. Our solution offers many advantages for miners- operational cost savings through visibility of fleet and assets, insights to load-unload cycles for appraising the efficiency of vehicles, automated trip management offering complete visibility and trip status, easy monitoring of underground assets and mining equipment with the use of Real-Time Location System & Location Based Services and flexible timing and scheduling of trips. The USPs of our integrated logistics systems are a centralized dashboard with drill-down capabilities for capturing heterogeneous data and a 360-degree view of the quantity of production, dispatch rate, and transporter's performance.

As the mining industry looks to balance profitability with sustainability, logistics optimization is the best bet. Emerging technologies like Artificial Intelligence (AI) and Robotic Process Automation (RPA) promise to mine the possibilities.

We will verify and publish your comment soon.