The global smart mining market was valued at USD 6.8 Billion in 2019 and is expected to reach USD 20.31 Billion by 2025, at a CAGR of 8.2% over the forecast period 2020-2025.

(Source; "Smart Mining Market - Growth, Trends and Forecasts (2020 - 2025))

The promising fourth industrial revolution - Industry 4.0 is defined by the use of “Internet of Things” capabilities and “Cyber-physical systems” in production processes in Industries. Industry 4.0 is a vision that evolved from an initiative to make the German manufacturing industry more competitive to a globally adopted term. The implementation of the Industry 4.0 project involves the creation of a smart industry that has evolved from the use of integrated information and communication control systems to digital systems.

The Internet of Things (IoT) has had a considerable impact on transforming multiple industries by forging real-time connections between machinery, environmental conditions, people, and business processes. This refers to the use of modern control systems, embedded with software systems and dispose of an Internet address to connect and be addressed via IoT (the Internet of Things). This way, products and means of production get networked and can ‘communicate’, enabling new ways of production, value creation, and real-time optimization.

The intelligent networking of machines and processes for the industry is what IIoT (Industrial Internet of Things) is. It is characterized by, more automation, bridging of the physical and digital world through cyber-physical systems, enabled by Industrial IoT, where smart products define the production steps with closed-loop data models & control systems and personalization/customization of products.

How Can IIoT Leverage Optimization in Mining?

The adoption of emerging technological trends and applications of the Internet of Things (IoT) in the industrial systems lead to the development of Industrial IoT (IIoT). Industry IoT has far-reaching use cases for the mining industry. IIoT can help overcome shortcomings of the traditional monitoring and control system while enabling companies to establish a unified monitoring system to automate processes, provide a safe working environment, enforce compliance effectively and control environmental situations.

The IIoT market is expected to grow from USD 77.3 Billion in 2020 to USD 110.6 billion by 2025, at a CAGR of 7.4% during the forecast period.

Industrial IoT (IIoT) Market by- Vertical, Region - Global Forecast to 2025:

Device & Technology (Sensor, RFID, Industrial Robotics, DCS Condition Monitoring, Networking Technology)

Connectivity (Wired, Wireless, Field Technology)

Software (PLM, MES, SCADA)

If one analyses the growing need & challenges in the mining landscape, IIoT has a crucial role to play. The increasing demands for production and cost reductions call for changes in the basic infrastructure, processes, and technology in the mining industry. The high penetration of advanced technology in the industry is projected to cut down significant costs of the workforce for the end-users, and hence, result in considerable cost optimization.

Further, advanced data analytics is being applied to the raw data to create visualizations, insights, and recommendations. This information is then delivered to mine managers and employees in real-time on their mobile devices.

For instance, CSM has been one of the first movers in the implementation of such solutions, since the past decade. It offers digital intervention and services for regulatory compliance. It has been a precursor in building operational infrastructure and showcase environmental value to our customers and stakeholders. In the course of actions, CSM has concentrated and provided solutions in Automation, Digitization and Robotics.

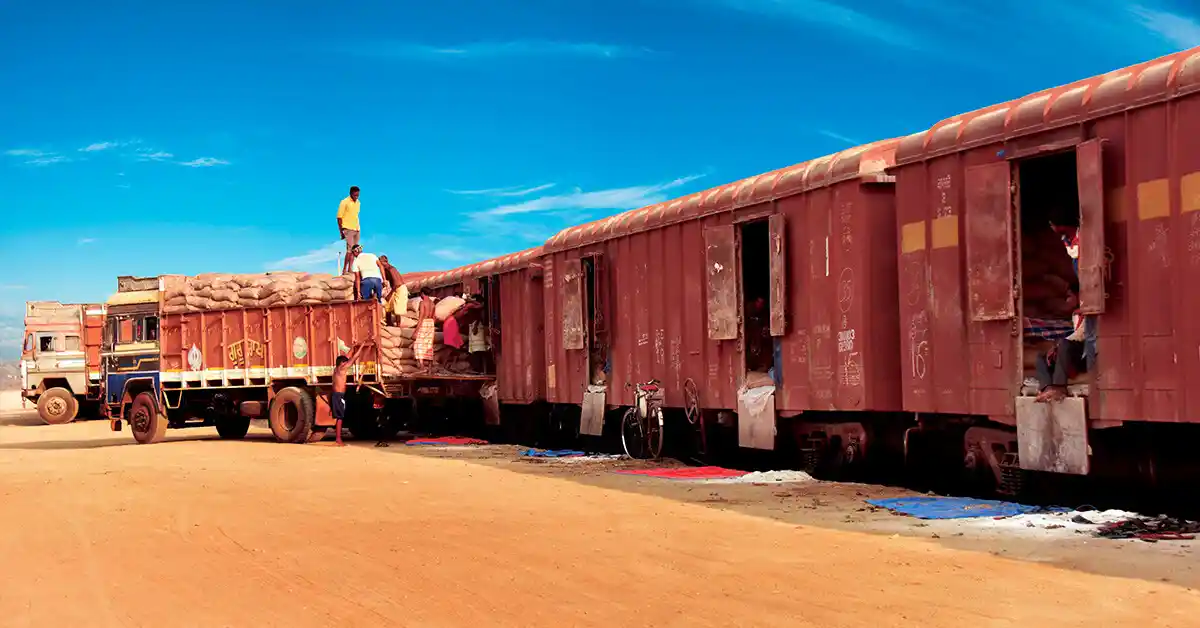

UAV based Surveillance Solution and Unmanned Weighbridge System are few of the solutions aimed at reducing human interventions and long Turn-Around Time (TAT) leading to a reduction in pilferage and revenue loss while facilitating enhanced productivity and monitoring.

The application of drones in the field of mining operations addresses gaps in the performance of periodic field activities, saves over 60-70% of man-hours while ensuring no data loss and minimal errors.

Unmanned Weighbridge System which has been implemented for stockyard management and automation at 6 weighbridges at Daitari Mines, Keonjhar, Odisha, facilitates and determines the weight of goods through the Tare & Gross weights of mineral carriers, without any human intervention. It

controls the efficient queuing and vehicle management of the mineral carrying containers right from the management of the RFID tags & readers on the windshields of the mineral carriers to the Boom Barriers that check the entry of carriers on the weighbridge.

Innovative disruption is possible using IoT, augmented and virtual reality (AR and VR), drone technology, artificial intelligence (AI) and computer vision combined with analytics. CSM has several solutions that tie them all together to bring new efficiency to the business and the workers in the mining domain.

We will verify and publish your comment soon.