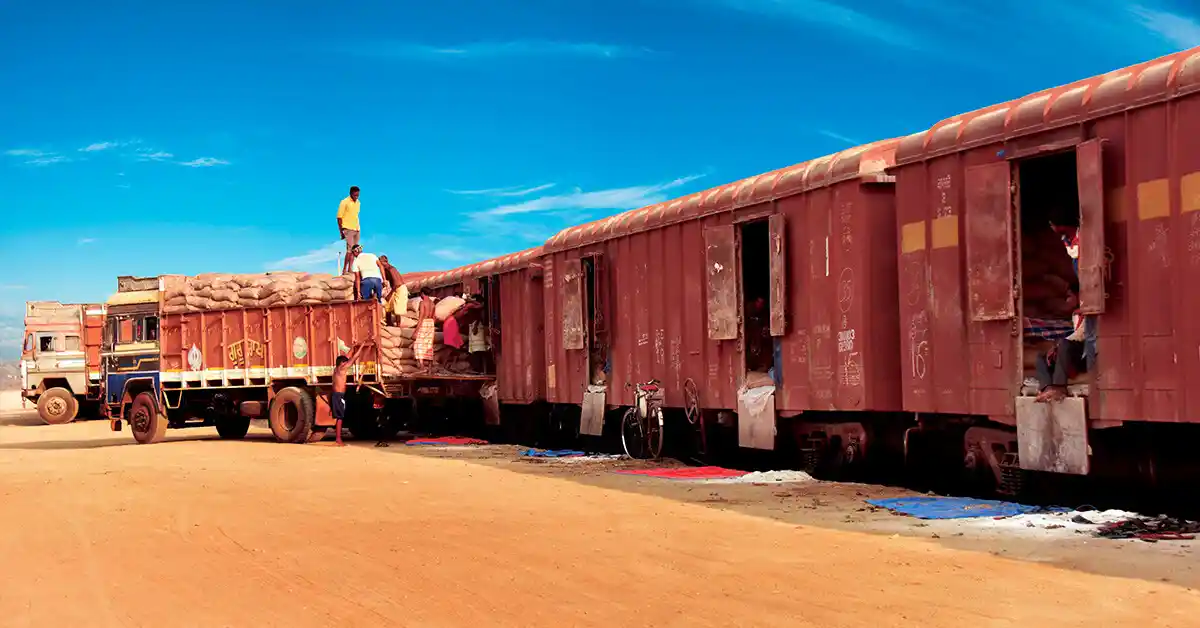

Think mining and the images that flash in your mind are rugged surfaces, the swirling dust, droning heavy equipment and cranes, rumble of trucks and so on. True- mining operates in harsh environmental conditions and remote locations. Both the siloed operations and the unfriendly terrain spawns a challenge to manage manpower and logistics. Integrated solutions offer a leap of promise- to transform the perception of mining from a labour and capital intensive industry to one fuelled by automation and predictive analytics. And, we are noticing the change. On how mining is getting increasingly tech driven. Today, you are still to get the real feel of ‘autopilot cars’ but ‘autopilot trucks’ in mining are a reality. The stage is not far when mines will not just be viewed as static repository of ores but dynamic ‘ore factories’.

How integrated mine solutions can shake-up processes

Mine operations need specific requirements and business processes that are unique to the industry. Historically, the mining industry supply chain is not fully integrated. Yes, many miners of global scale have been deploying technology powered applications but they are unconnected. For example, mining companies have separate applications for mine planning, truck dispatch, plant automation, production recording, and other systems.

With government policies gradually getting aligned with emerging technologies like Artificial Intelligence, Internet of Things (IoT) and Robotics, miners are warming up to the idea of end-to-end solutions, especially the ones that use these game changing technologies. Not only are these technologies efficient, they are the best bet to substitute cumbersome and dicey human interventions. That’s because technology helps them to navigate a pressing challenge- optimizing productivity at the lowest possible costs and balancing it with the safety of the workforce. A related problem here is data entry and collection through error prone manual practices. Stakeholders in mining need accurate information on production and transport of ore for export or domestic movement. This is where automated processes powered by real-time analytics and IoT technology can deliver efficient and accurate results. Let’s say, you can fit sensors into the mining machines that can capture and transmit data real time to your connected systems.

Integration of mine solutions connects people and equipment in real time to perform an array of operations. They also mine other benefits such as real-time visibility on material movement, enhanced productivity, data accuracy, reduced manpower costs, integrated view of operations across mines and financial integration from the beginning of a mining project.

i3MS: Our disruptor in Mine Management

Started in 2010, the Integrated Mines and Minerals Management System (i3MS) was envisaged as an end-to-end ore tracking and accounting system. The system tracks the entire cycle ore from extraction to evacuation. With its embedded features, i3MS ensures strict compliance with the multi-layered mining laws as every single tonne of ore moved from the pit to the wagon and ports is accounted for. India produces over 900 million tonnes of major minerals and coal each year and the i3MS system alone handles around a third of this volume. Being an online repository of orders and documents, the system offers online applications of all administrative approvals, tracks mineral transportation from the source to destination, facilitates online payment of rents and auto calculates royalty. I3MS is seamlessly integrated with the Freight Operation Information System of Railways, Regional Transport Office (RTO), ports, FASTag electronic toll collection of NHAI as well as Income Tax and GST data registry. The use of IoT devices ensures that the weight of minerals is auto captured in more than 1300 despatch points every day, ruling out the possibility of manipulation or duplication.

In recognition of its strengths, the Union mines ministry has applauded i3MS as a ‘model project’, recommending the solution to states producing major and minor minerals. Today, i3MS pivots the transparent movement of ore in major mineral producers of the country like Odisha, Jharkhand, Bihar and is on course to be on boarded by the Chhattisgarh mines department. So, how does i3MS stand out from vanilla online mine management solutions? The integrated solution enables verification of clearances, validity and returns, generation of e-permit, system generated e-transit pass, electronic verification and surveillance check gates on identified routes etc. Also, i3MS operates round the clock, recording around 100,000 transactions every day- this translates into approximately 70 transactions per minute.

The i3MS is a robust IT intervention to curb illegal mining and promote Ease of Doing Business (EoDB). GovTech solutions are playing a key role in easing business processes and preparing the ground for Industry 4.0 with focus on automation. In sync with this government vision, mining companies need to tune in to automated systems for safety, feasibility, profitability and an immersive user experience.

We will verify and publish your comment soon.