.jpg)

Mineral resources constitute a crucial revenue stream for the African continent. In the year 2019, minerals and fossil fuels contributed to over one-third of exports from at least 60 percent of African nations. The continent's production of approximately 80 percent of the world's platinum, two-thirds of its cobalt, half of its manganese, and a significant quantity of chromium places it in a favorable position to capitalize on the escalating demand for these minerals. Additionally, Africa is reputed to possess some of the world's most extensive unexplored mineral reserves.

Regrettably, the absence of comprehensive geological mapping and exploration has resulted in an incomplete understanding of the entirety of the continent's resources. In order to fully harness the potential of mineral-rich African nations, it is imperative for mining companies and African governments to adopt emerging technologies. The integration of technologies like artificial intelligence (AI), machine learning, GIS, robotic process automation and big data analytics can assist mining enterprises in mitigating environmental risks, improving labor conditions, reducing operational expenses, and augmenting productivity.

For example, despite generating vast amounts of data throughout their operations, only a few mining companies utilize it in a manner that provides tangible value. This represents a significant missed opportunity, as advanced analytics can optimize mine planning, increase yields, and reduce equipment downtime. In South Africa, a 30-year-old mine was able to increase its mineral recovery by 2 percent by applying advanced analytics to its primary processing steps.

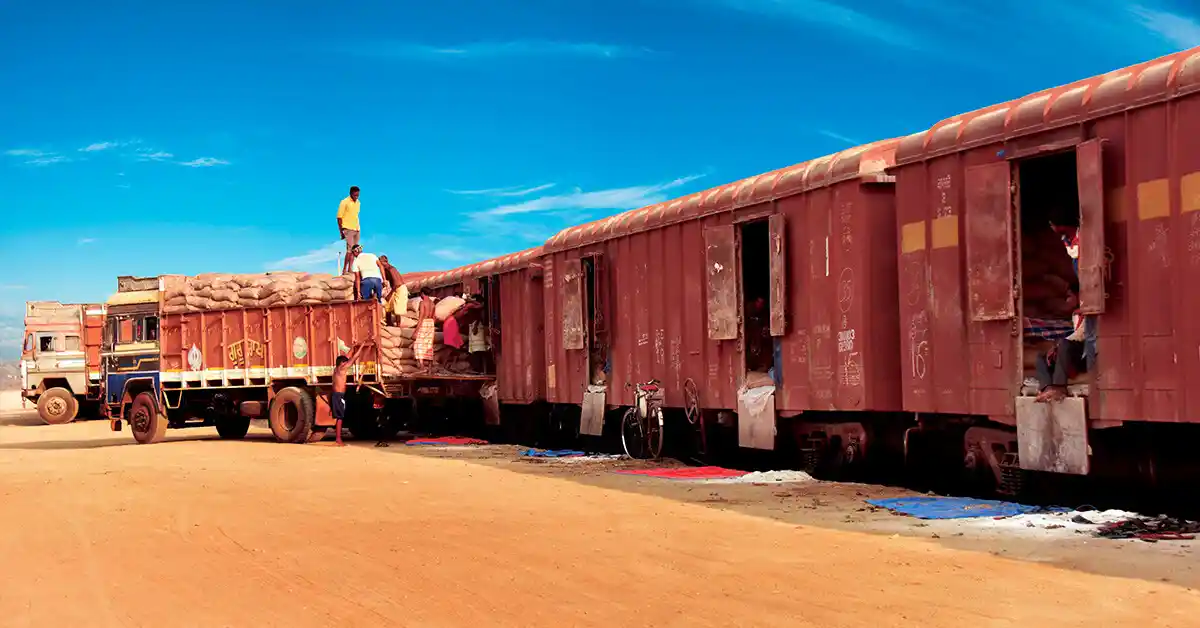

The Syama mine in Mali serves as a prime example of a site that has reaped the benefits of digitalization. In 2015, Resolute Mining assumed control of operations at Syama and successfully transformed it into the world's inaugural purpose-built automated mine. Through the utilization of a fiber-optic network linked to control centers situated above ground, employees are able to effectively manage and monitor all activities, ranging from the initial clearing of the drill point to the subsequent extraction, loading, and hauling processes. Despite the substantial initial investment required, these changes are projected to reduce mining costs by 30 percent and enhance overall efficiency. Notably, the machines are capable of operating for 22 hours per day, eliminating any time lost due to shift changes.

It is also crucial to recognize that the economic advantages of digitalization extend to both governments and local communities. As mines become more productive and profitable, national governments will realize increased revenue to allocate towards infrastructure investments such as roads, schools, and health clinics.

Mining operations that embrace the digital transformation will witness heightened production levels, enhanced efficiency and effectiveness, and a greater commitment to environmental sustainability. In essence, they will disrupt Africa's mining sector; however, if harnessed correctly, the benefits of digitalization will far outweigh the associated risks.

We will verify and publish your comment soon.