Introduction to SCADA Systems

SCADA (Supervisory Control and Data Acquisition) systems play a critical role in modern industry, allowing operators to monitor, control, and optimize industrial processes across sectors such as manufacturing, utilities, energy, and transportation. By centralizing operations, SCADA provides real-time data insights and enables efficient automated control, ensuring smooth, reliable, and safe operations. As industries evolve and become more complex, SCADA systems integrate cutting-edge technologies, such as IoT (Internet of Things), to deliver smarter and more secure management solutions. These systems not only drive productivity but also help minimize operational risks, optimize resource management, and ensure compliance with safety and regulatory standards.

.jpg)

Challenges Without SCADA Systems

Industries face a variety of challenges without SCADA. Here are a few examples:

- Operational Inefficiencies: Lack of real-time visibility into operations leads to inefficiencies, increased downtime, and reliance on manual intervention.

- High Maintenance Costs: Without predictive monitoring, unplanned downtimes and equipment failures become frequent and costly.

- Difficulties with Remote Monitoring: Infrastructure located in remote areas, such as pipelines or water management facilities, becomes challenging to monitor regularly without SCADA.

- Data Management: High volumes of data, like those generated in power plants, need to be efficiently stored, analyzed, and used to make timely decisions.

- Safety and Compliance Risks: Hazardous environments, such as those in chemical manufacturing, require constant monitoring to prevent accidents and meet regulatory requirements.

- Cybersecurity Vulnerabilities: Industrial systems are increasingly interconnected, making them vulnerable to cyber threats without a centralized, secure system.

- Integration of Legacy Systems: Many industries still rely on standalone, older systems that are not optimized for modern data-driven decision-making.

Why SCADA Systems Are Essential

Implementing a SCADA system can be transformative for industries reliant on real-time data and centralized control. Here are some of the major benefits:

- Real-Time Monitoring: SCADA systems continuously gather data, allowing for instant oversight of processes and quick response to any issues that arise.

- Increased Efficiency: By automating routine tasks, SCADA optimizes resources and increases productivity, helping reduce the need for manual intervention.

- Predictive Maintenance: Advanced analytics in SCADA systems can identify maintenance needs early, reducing costly downtime and extending the life of equipment.

- Centralized Data Management: Consolidating data from multiple processes into one platform simplifies analysis and strategic planning.

- Enhanced Safety and Compliance: SCADA systems monitor hazardous conditions, triggering automated emergency protocols and ensuring adherence to safety regulations.

- Remote Control: Operators can monitor and control processes from anywhere, which is especially useful for operations spread across remote or inaccessible areas.

- Cost Savings: Automation and resource optimization within SCADA reduce waste, leading to substantial savings in operating costs.

Key Components of SCADA Systems

- SCADA Server: The central hub for data collection, processing, and visualization.

- OPC Client and Server: Facilitates communication between SCADA systems and other industrial control devices.

- Programmable Logic Controller (PLC): Essential for real-time monitoring and automation of industrial equipment.

- Human-Machine Interface (HMI): Displays data and allows operators to interact with the system.

- Database : Stores and logs data for analysis and auditing.

- Power BI (Business Intelligence): For in-depth analysis and reporting.

- Alarming and Event Management: Triggers alerts and manages responses to specific operational events.

SCADA System’s Application:

- Energy Sector: SCADA systems monitor and control energy distribution across power grids, balancing loads and managing outages. Renewable energy providers, like wind and solar farms, use SCADA for optimized energy production and remote equipment monitoring.

- Water and Wastewater Management: SCADA automates water distribution, controls pumps, and monitors reservoir levels, ensuring optimal resource use and regulatory compliance.

- Oil and Gas: SCADA oversees pipeline monitoring, leak detection, and refinery automation, ensuring safety and efficiency in these high-stakes environments.

- Manufacturing: SCADA controls and monitors production lines, facilitating quality control and efficiency across various production stages.

- Transportation and Logistics: Railways and ports use SCADA for monitoring equipment status, managing schedules, and enhancing operational efficiency.

- Building Automation: In smart buildings, SCADA manages HVAC, lighting, and security systems to optimize energy use and occupant comfort.

- Agriculture: SCADA automates irrigation and monitors livestock conditions, enhancing resource use and supporting higher crop yields.

.jpg)

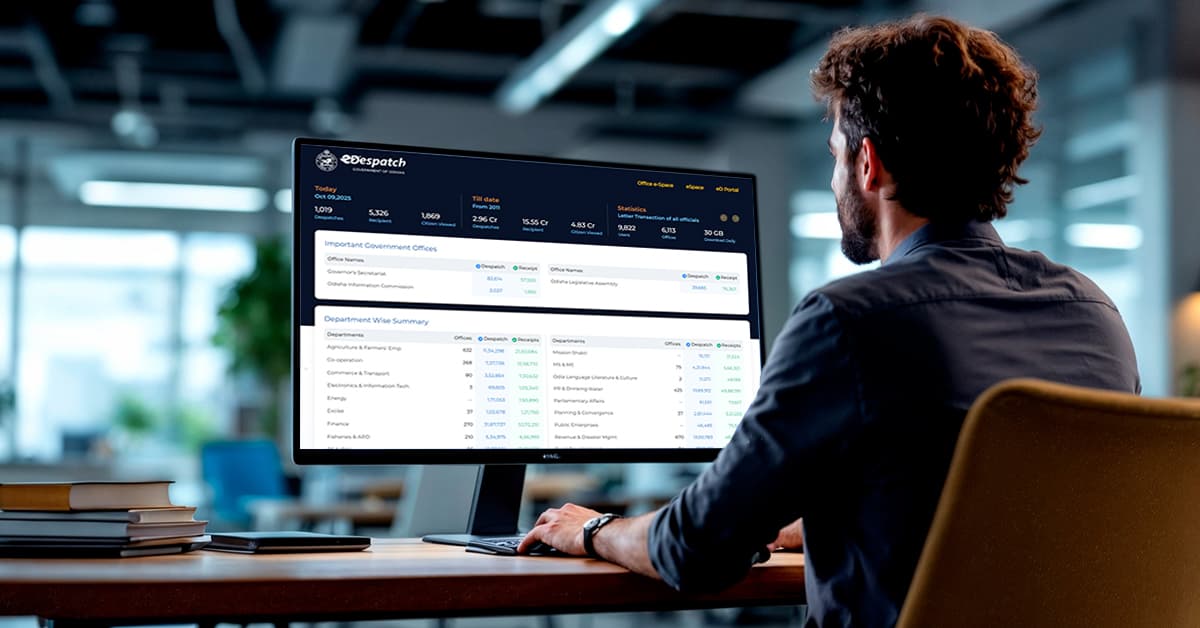

CSM’s Integrated SCADA Platform empowers industrial facilities by unifying multiple systems into a centralized dashboard that enhances data visualization and decision-making. It offers real-time data collection, processing information every 50 milliseconds, which, paired with IoT integration, allows for predictive maintenance, remote monitoring, and optimized resource usage. With advanced security protocols to protect data integrity and secure communication, CSM’s SCADA platform is scalable, easily integrating with existing systems and enabling data-driven decisions to streamline operations and support business growth.

Conclusion

SCADA systems are integral to the industrial sector, providing the tools necessary for effective, automated, and centralized process control. As industrial demands evolve, SCADA continues to incorporate IoT, data analytics, and enhanced security to offer a robust solution that optimizes operational efficiency and ensures safety. The adaptability, scalability, and centralized control provided by SCADA systems make them essential for industries looking to stay competitive and resilient in a rapidly changing technological landscape.

.jpg)

We will verify and publish your comment soon.