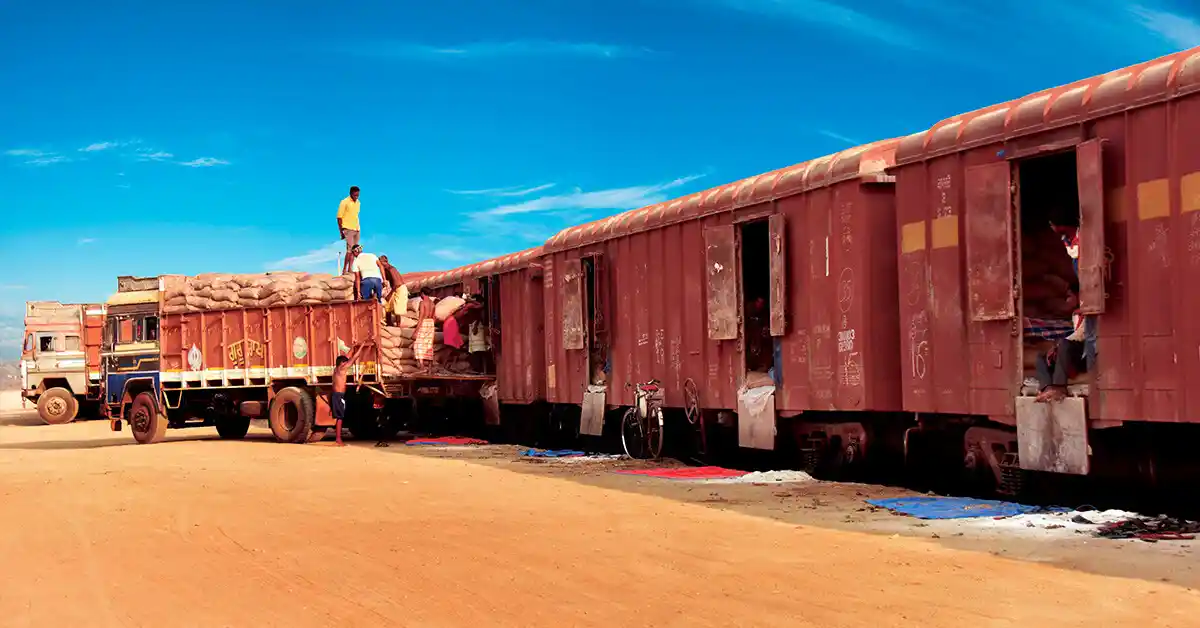

The mining industry operates in extreme conditions where efficiency, safety, and compliance are paramount. Managing heavy vehicles in vast, remote mining sites is a complex task that requires real-time data and seamless coordination. According to industry reports, the global mining fleet management market is projected to grow at a CAGR of 15.2% from 2023 to 2030, driven by the increasing adoption of digital tracking solutions and automation.

![]()

Current Challenges in Mining Vehicle Operations

Despite technological advancements, mining companies face several challenges in managing their vehicle fleets effectively:

- Operational Inefficiencies: Poor fleet management leads to longer cycle times, delays in material transportation, and underutilization of assets, directly impacting productivity.

- Fuel Consumption & Costs: Heavy mining vehicles are fuel-intensive, and inefficient route planning or excessive idling contributes to increased operational expenses.

- Vehicle Maintenance & Downtime: Unplanned breakdowns lead to delays in operations and higher maintenance costs, affecting overall output.

- Regulatory Compliance: Mining companies must adhere to strict environmental and safety regulations. Non-compliance can result in penalties and operational disruptions.

The Need for Heavy Vehicle Tracking Systems

Implementing a Heavy Vehicle Tracking System (HVTS) is essential for overcoming these challenges. A robust tracking system enables:

- Real-Time Monitoring: GPS-based tracking provides live location updates, ensuring better coordination of vehicle movement across the mining site.

- Optimized Fleet Utilization: Data-driven insights help in reducing idle time, optimizing load cycles, and improving route planning for efficient operations.

- Predictive Maintenance: Continuous tracking of vehicle health enables proactive maintenance, reducing downtime and extending equipment lifespan.

- Fuel Efficiency & Cost Reduction: Smart tracking systems analyze fuel consumption patterns, helping companies implement strategies to reduce wastage and improve fuel efficiency.

- Compliance & Reporting: Automated logs ensure accurate documentation of vehicle activities, aiding in compliance with environmental and operational regulations.

CSM Tech’s Heavy Vehicle Tracking System

CSM Tech offers an advanced Heavy Vehicle Tracking System tailored to the mining industry's needs. The solution integrates IoT, beacon technology, and AI-driven analytics to provide comprehensive visibility into fleet operations. Key features include:

- Geofencing for restricted zones to enhance safety.

- Integration with unmanned weighbridge systems for automated weight monitoring.

- Digital logistics management solutions for seamless tracking from pit to port.

By leveraging real-time data and automation, CSM Tech’s solution enables mining companies to streamline operations, improve efficiency, and ensure regulatory compliance.

Conclusion

In an industry where efficiency and safety define success, Heavy Vehicle Tracking Systems are no longer an option but a necessity. Companies that adopt smart tracking solutions gain a competitive edge by enhancing fleet productivity, reducing costs, and improving compliance. As the mining sector continues to embrace digital transformation, investing in data-driven fleet management will be key to sustaining long-term growth.

We will verify and publish your comment soon.